On a seemingly ordinary day in January 1919, the city of Boston was struck by one of the most bizarre and devastating industrial accidents in American history—the Great Molasses Flood. This tragic event not only claimed lives but also spurred significant changes in industrial regulations and public safety measures.

The disaster unfolded in the bustling North End neighborhood of Boston, a district known for its dense population and industrial activity. At the heart of the catastrophe was a massive storage tank owned by the United States Industrial Alcohol Company (USIA). This tank, measuring 50 feet in height and 90 feet in diameter, contained approximately 2.3 million gallons of molasses, a common ingredient in the production of munitions. The molasses was also used in the fermentation process to produce alcohol, a lucrative business during the era of World War I.

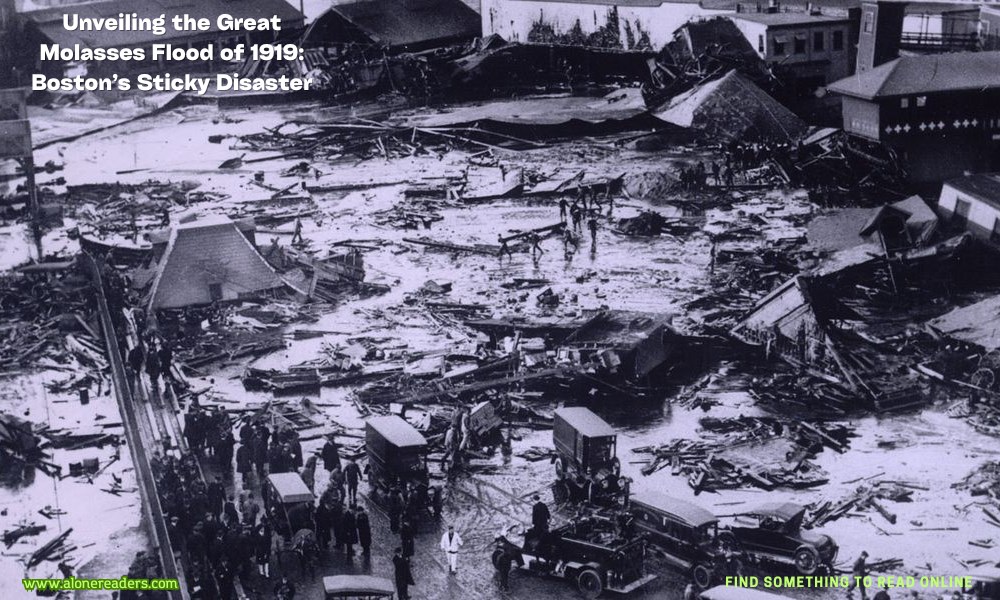

On January 15, under the strain of a recent delivery that filled it to near capacity, and possibly aided by the unseasonably warm temperatures that day, the tank burst. The result was a wave of molasses up to 25 feet high, racing through the streets at 35 miles per hour. The dense, sticky substance engulfed everything in its path, including people, horses, vehicles, and buildings. The force was so powerful it caused buildings to crumble and the elevated railroad tracks were significantly damaged.

The human toll was heartrending. Twenty-one people lost their lives and over 150 were injured. The victims included workers, residents, and children who were either crushed by the debris or drowned in the molasses. Rescue efforts were hampered by the viscous syrup, complicating the already frantic attempts to save those who were trapped.

Beyond the immediate human tragedy, the flood caused extensive damage to the North End. The cleanup operation was enormous, requiring several weeks to remove the molasses from the streets, buildings, and harbor. Residents claimed that on hot summer days, the area would smell of molasses for decades thereafter.

The aftermath of the flood raised numerous questions about industrial safety and the responsibilities of corporations. It was discovered during subsequent investigations that the tank had been hastily constructed and inadequately tested. Engineers and safety inspectors had not properly reviewed the structure, which was known to leak so profusely that locals would collect molasses from the drippings. The company's lack of attention to safety standards and its disregard for potential danger came under severe scrutiny.

The legal battles that followed were extensive and groundbreaking. More than 100 lawsuits were filed against the United States Industrial Alcohol Company. The litigation set a legal precedent in corporate responsibility for industrial accidents, leading to more stringent regulations and safety standards nationwide. It was one of the first times a U.S. court ruled that a company could be held liable for damages due to negligence, setting a precedent for modern corporate regulation.

This disaster also had a profound effect on engineering practices. It led to increased requirements for engineering certifications and more rigorous building inspection practices, especially for structures that held hazardous materials. The tragedy underscored the importance of ethical engineering and meticulous adherence to safety protocols.

The Great Molasses Flood remains a stark reminder of the potential human cost of neglecting industrial safety. It serves as a case study in the development of safety regulations and the ongoing need for vigilance in industrial operations. As we look back on this sticky yet somber chapter of Boston's history, it is a testament to the city's resilience and its commitment to improving public safety in the wake of tragedy. Through understanding such past incidents, we can better prepare for and prevent future industrial disasters.