Liquefied natural gas, or LNG, has become one of the most critical fuels of the twenty-first century, offering a cleaner alternative to coal and oil while ensuring energy security for countries far from natural gas reserves. The lifeline of this global LNG trade is carried not through pipelines, but across oceans in enormous vessels known as LNG megacarriers. These ships represent the pinnacle of maritime engineering, combining cryogenic technology, advanced hull design, and powerful propulsion systems to transport vast quantities of gas safely and efficiently. LNG megacarriers are not just ships; they are floating marvels of science and technology, enabling the globalization of energy markets in an era where demand for natural gas continues to surge.

The defining characteristic of LNG transport is its cryogenic nature. Natural gas becomes liquefied only when cooled to approximately –162°C, shrinking to about 1/600th of its original volume. This extreme reduction makes ocean transport possible, but it comes with immense engineering challenges. The tanks aboard LNG megacarriers must be capable of holding this frigid liquid while withstanding the stresses of long voyages through turbulent seas. Insulation is crucial: the tanks are constructed with multiple layers of specialized materials to minimize boil-off gas, the natural evaporation of LNG during transit. Some of this evaporated gas is harnessed as fuel, providing a cleaner-burning energy source for the ship’s engines, demonstrating a clever integration of design and sustainability.

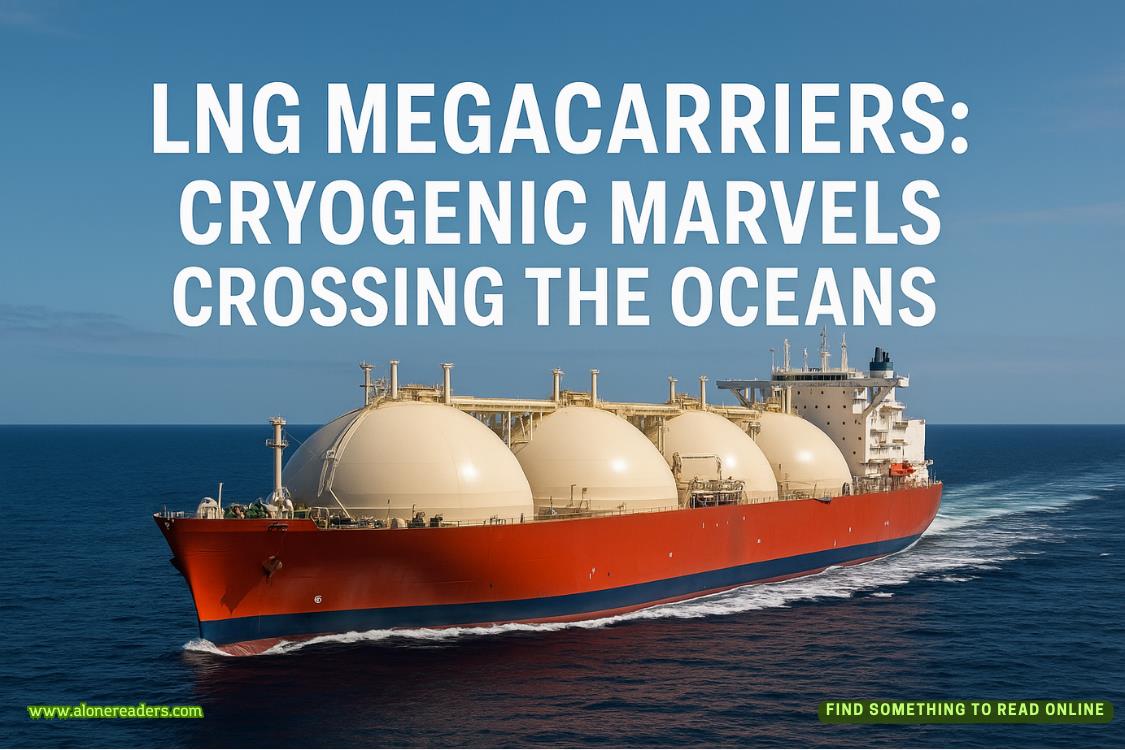

Modern LNG megacarriers can exceed lengths of 300 meters and carry upwards of 266,000 cubic meters of LNG in a single voyage. To visualize, that volume is equivalent to nearly 100 Olympic swimming pools filled with liquefied gas. The tanks that store this fuel come in two main designs: the Moss-type spherical tanks, easily recognizable for their dome-like structures visible above deck, and the membrane-type tanks, which are integrated into the hull and covered with insulation layers. Membrane systems dominate the newest generations of megacarriers because they maximize cargo space while offering flexibility and efficiency. Their modular nature allows shipbuilders to optimize capacity for specific routes and terminal infrastructures.

The operation of these massive vessels is an orchestration of precision. Crews onboard manage temperature, pressure, and safety systems with constant monitoring to prevent any leaks or uncontrolled boil-off. Cargo handling systems are designed to maintain balance while loading and unloading the LNG, which is transferred using cryogenic pumps and pipelines to shore-based storage facilities. Ports that receive LNG megacarriers are equipped with specialized terminals, including insulated storage tanks and regasification plants that convert the liquid fuel back into gaseous form for distribution through national grids. The entire chain, from ship to shore, is a tightly controlled process that minimizes risk while maximizing efficiency.

Propulsion technology has evolved in parallel with cargo systems. Earlier LNG carriers relied on steam turbines fueled by boil-off gas, but this method was relatively inefficient compared to modern alternatives. Today’s megacarriers often use dual-fuel diesel-electric (DFDE) or ME-GI (high-pressure gas injection) engines that can burn both natural gas and marine diesel. This not only reduces emissions but also offers flexibility in fuel choice depending on voyage conditions. Furthermore, shipbuilders have focused on optimizing hull hydrodynamics to reduce drag and improve fuel efficiency. Even minor improvements in efficiency have enormous financial implications, given the scale of global LNG trade and the high operating costs of these vessels.

Global energy demand has shaped the rise of LNG megacarriers. As nations transition away from coal and oil, natural gas has emerged as a bridge fuel for the renewable energy era. Countries such as Japan, South Korea, and China are among the largest LNG importers, relying on these vessels to power industries and households. Exporting nations like Qatar, Australia, and the United States dominate LNG production, sending vast fleets of megacarriers across busy shipping lanes. The widening Panama Canal and the growing Arctic routes have opened new possibilities for LNG logistics, reducing voyage times and creating fresh challenges for naval architects designing ships capable of withstanding icy waters.

Safety is at the heart of LNG shipping. Despite carrying vast quantities of highly flammable fuel, LNG megacarriers have a strong safety record thanks to rigorous international regulations and advanced ship design. International bodies such as the International Maritime Organization (IMO) set strict guidelines for LNG transport, including double-hulled construction, advanced fire-suppression systems, and emergency shutdown mechanisms. The training of crew members is equally vital, ensuring they can respond to extreme scenarios ranging from cryogenic leaks to onboard fires. The industry’s emphasis on safety reflects not only its responsibility to protect human life but also the economic importance of ensuring uninterrupted LNG supply chains.

The economics of LNG megacarriers are staggering. Building a single vessel can cost more than $200 million, and charter rates vary depending on global demand, often reaching hundreds of thousands of dollars per day. For energy companies, securing shipping capacity is as crucial as maintaining production, since LNG must move continuously to meet contracts and national needs. During times of geopolitical tension or supply disruptions, LNG carriers can become strategic assets, redirecting cargoes to nations in need. The flexible nature of LNG shipping, compared to fixed pipelines, makes it an indispensable element of modern energy security.

Environmental considerations are also shaping the future of LNG shipping. While natural gas is a cleaner-burning fossil fuel, the shipping process itself contributes to greenhouse gas emissions. To address this, shipbuilders and operators are adopting new technologies such as carbon capture integration, improved hull coatings to reduce biofouling, and digital monitoring systems that optimize routes and speeds. Some projects are even exploring LNG carriers fueled by hydrogen or ammonia in the future, reflecting the broader shift in maritime industries toward decarbonization. The megacarrier of tomorrow may not only transport LNG but also embody the transition to new energy paradigms.

The symbolic significance of LNG megacarriers extends beyond engineering. They represent a form of global interdependence: nations that lack natural gas reserves rely on these vessels to secure their energy supplies, while producers depend on them to reach distant markets. Every voyage connects continents, linking energy-rich nations to energy-hungry economies. In an era marked by shifting alliances, climate change, and energy transformation, LNG megacarriers stand as both a technological triumph and a geopolitical instrument.

As global energy systems evolve, LNG megacarriers will remain essential players for decades to come. Their cryogenic tanks, massive scale, and sophisticated propulsion systems exemplify how humanity solves complex challenges through engineering innovation. More than just ships, they are the silent giants ensuring lights stay on, industries continue running, and nations achieve their energy goals. They cross the oceans not only as vessels of fuel but as symbols of the interconnected world, navigating the fine balance between economic growth, technological advancement, and environmental stewardship.