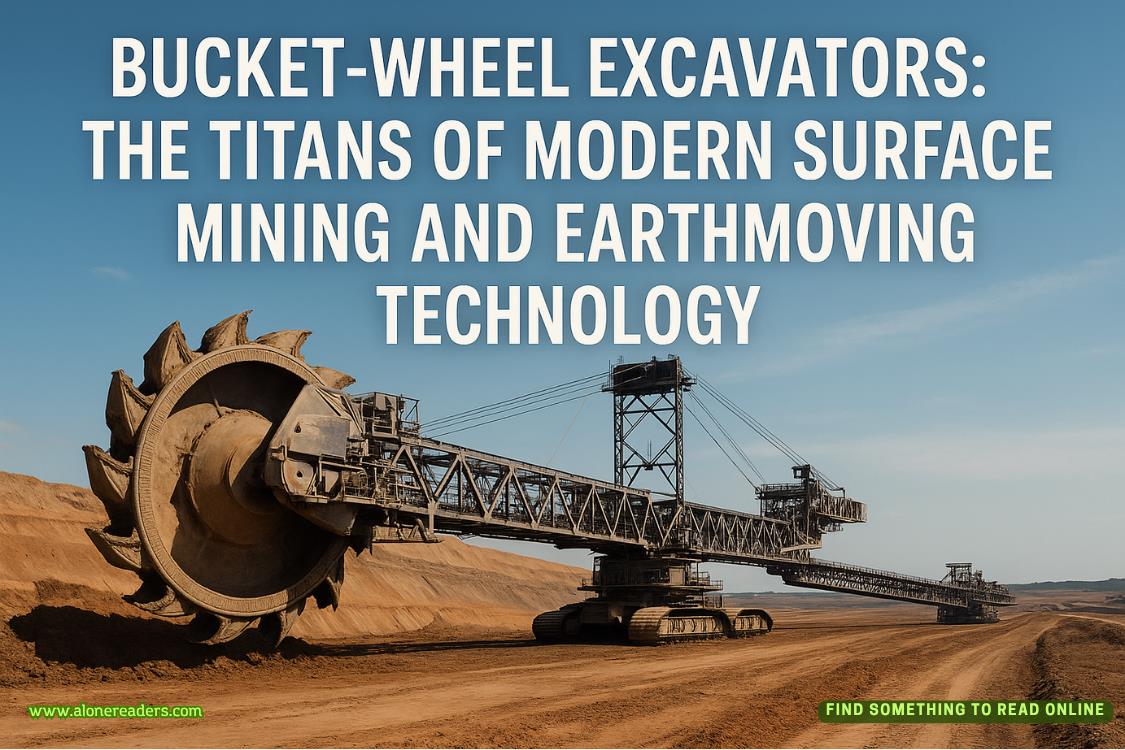

Bucket-wheel excavators are among the most colossal mobile machines ever engineered by humans. Towering hundreds of feet high, stretching longer than some skyscrapers are tall, and weighing thousands of tons, these mechanical behemoths are designed for one purpose—moving extraordinary volumes of earth with relentless efficiency. From the vast surface mines of Germany’s Rhineland to lignite pits in Eastern Europe and massive coal fields across Asia, bucket-wheel excavators represent the pinnacle of continuous excavation technology. Their unmistakable design, defined by a rotating wheel lined with scooping buckets, allows them to devour earth at a scale that defies ordinary industrial comparison. While people often marvel at rockets, bridges, or aircraft carriers, the sheer endurance, mobility, and operational output of these machines place them among the quiet titans of modern industry.

A bucket-wheel excavator’s core concept is simple in principle: attach a massive wheel to a boom, fill its circumference with buckets, and rotate it continuously into a bank of earth. As the wheel spins, the buckets scoop material, deposit it onto a conveyor belt system, and ultimately transport it away for processing or disposal. What begins as a simple mechanical motion becomes a highly choreographed ballet of industrial power when performed at the scale of several thousand tons of moving machinery. Models like the Bagger 293, built by Germany’s TAKRAF, stand over 300 feet tall, extend more than 700 feet in length, and weigh roughly 14,000 tons. These measurements are not engineering indulgence; they are necessary to maintain stability and reach vast excavation surfaces without frequent repositioning. Their mobility is equally astonishing. Though slow, traveling often at less than one kilometer per hour, these machines move on massive tracked platforms that evenly distribute their enormous weight across soft earth surfaces, preventing them from sinking.

Unlike traditional excavators, bulldozers, or haul trucks that work in cycles—digging, lifting, dumping—bucket-wheel excavators operate continuously. This continuous operation is what grants them immense productivity advantages. While a typical mining shovel must pause between cycles, a bucket wheel never stops rotating as long as power reaches its electric motors. Many operations pair them with long conveyor belts stretching miles across the mining complex, creating an unbroken stream of ore or overburden flowing to crushing plants, sorting facilities, or spoil piles. This creates a highly efficient logistical chain that substantially reduces labor demand, fuel consumption, and equipment downtime. In fact, a single bucket-wheel excavator can replace dozens of traditional vehicles. At peak capacity, some models can remove up to 240,000 cubic meters of material per day, equivalent to digging an entire football field more than 100 meters deep daily. This staggering output is why such machines largely define strip mining and lignite extraction strategies in many regions.

The engineering behind these machines is a triumph of industrial design, mechanical strength, and energy management. Their buckets must withstand abrasive material while maintaining precise geometry, and their wheel booms must remain structurally rigid while extending hundreds of feet from the main chassis. The torque delivered to the wheel shafts is massive, and the electrical systems powering them require robust distribution networks. Engineers must also account for dynamic loads as the wheel meets geological layers of varying hardness. Reinforced steel structures, hydraulic supports, and computerized load monitoring systems work simultaneously to prevent catastrophic stress failures. In modern variants, sensors track vibration, bucket wear, bearing friction, and conveyor alignment. Automated lubrication systems ensure minimal mechanical drag. Remote diagnostic interfaces allow technicians to assess health data in real time, which is crucial given the catastrophic costs of downtime.

Although these machines are technological marvels, they are inherently specialized. Their primary domain is in soft to moderately hard geological formations where continuous shaving of soil, clay, and lignite layers is feasible. Hard rock mines rarely employ bucket wheels, as their cutting tools would wear too quickly and the forces required would exceed practical engineering limits. Instead, bucket-wheel excavators thrive in regions rich with coal seams near the surface. They remove overburden to expose valuable layers below, or directly harvest lignite deposits. Regions such as Germany’s Lusatian and Rhineland basins have become internationally recognized examples of surface mining landscapes shaped by these machines.

However, their enormous productivity is intertwined with complex environmental and societal consequences. The landscapes reshaped by bucket-wheel excavators are often unrecognizable after years of operation. Entire villages have historically been relocated to extend lignite extraction fields. Topsoil removal disrupts ecosystems, groundwater behavior changes, and dust generation becomes a frequent concern. Modern mining regulations attempt to mitigate such effects through reclamation requirements, but the visual scars left behind can remain for generations. Critics point to bucket-wheel operations as symbols of industrial-scale environmental disruption, especially as nations grapple with carbon reduction targets. Coal-dependent economies, while aware of the environmental cost, maintain reliance on these machines due to energy demand stability and economic inertia.

Despite their environmental drawbacks, the industry has gradually shifted toward better practices. Progressive reclamation strategies restore mined land in parallel with ongoing excavation. Conveyor dust suppression systems reduce airborne particulates. Water management has become more sophisticated, preventing harmful runoff. In countries transitioning away from coal, bucket-wheel excavators are gradually being decommissioned or repurposed. Some former mining pits transform into artificial lakes, nature preserves, or industrial tourism attractions. Ironically, decommissioned machines themselves become cultural monuments. Tourists stand in awe beneath their towering frames, marveling at machinery that once dominated the earth but now rests quietly under the sky.

One of the most interesting engineering challenges is mobility. Moving a multi-thousand-ton machine across uneven terrain requires continuous ground assessment. Survey teams evaluate soil compaction, subsurface stability, and slope tolerance. As the machine inches forward, its tracks shift independently to maintain balance. Hydraulic leveling systems keep the central structure horizontal to prevent stress imbalances across the boom. Even with careful planning, relocations can take days and require specialized crews. If an excavator must cross public infrastructure such as roads or pipelines, temporary support structures are built to distribute weight safely. This logistical complexity means that bucket-wheel excavators are rarely transported between mines; they are typically assembled on-site and remain in the same region for decades.

Power consumption is another defining characteristic. Large machines often require tens of megawatts of electricity, supplied directly from regional grids or dedicated substations. Operating costs are high, but the return in extracted volume justifies the expense. Because many mines operate continuously, bucket-wheel excavators frequently run around the clock, supported by large maintenance teams. Crews work in shifts, performing routine inspections on bearings, gearboxes, and conveyor alignment. Bucket replacement, though performed regularly, must be timed to minimize downtime. Welding crews, electricians, and hydraulic technicians form the backbone of these support operations. Without constant care, even the strongest steel weakens under relentless mechanical stress.

The strategic relevance of bucket-wheel excavators extends beyond mining alone. Their conceptual design influences other industries focused on large-volume earthmoving, such as massive dredging operations or continuous trenching machines used in pipeline installation. They represent a philosophy of constant, incremental removal rather than cyclical excavating—an approach that reduces unnecessary energy expenditure. This continuous flow principle is also reflected in modern manufacturing and logistics systems, proving that even mining equipment can shape broader engineering thinking.

Looking toward the future, the role of bucket-wheel excavators will inevitably evolve. As countries ramp up renewable energy production, demand for coal may decline, particularly in Europe. Still, lignite remains significant in some markets, ensuring continued operation for decades. Meanwhile, evolving sensor technology, automation, and artificial intelligence may transform how these machines are operated. Autonomous excavation control systems could adjust wheel speed, bucket force, and boom angle in response to real-time geological sensing. Predictive maintenance algorithms will anticipate component fatigue before mechanical failure occurs, reducing downtime and extending machinery lifespan. Energy efficiency improvements may reduce the ecological footprint of ongoing operations.

Some visionary proposals suggest adapting bucket-wheel technology for entirely new Earthmoving challenges. Large-scale land reclamation, coastal reshaping, or even ambitious terraforming projects could theoretically benefit from continuous excavation machinery. Although speculative, these concepts highlight the extraordinary power represented by machines capable of reshaping terrain at industrial speed.

In popular culture, bucket-wheel excavators frequently appear in documentaries, industrial photography, and media emphasizing humanity’s relationship with the Earth. When captured from drone footage, they resemble metal leviathans carving geometric patterns into the countryside. Their imposing forms raise philosophical questions about scale, environmental stewardship, and technological ambition. While humans have the ingenuity to build such machines, they also carry responsibility for managing the consequences of their use.

In the end, bucket-wheel excavators stand as symbols of industrial capability, engineering creativity, and resource demand. They are machines that combine structural might, electrical power, and logistical sophistication into a single purpose: the relentless excavation of earth. Though their future may shift alongside changing energy priorities, their legacy will remain literally carved into landscapes across the world. For engineers, historians, and environmental planners, these gargantuan excavators represent both the achievements and challenges of our industrial era. Through them, we witness how far engineering can push physical boundaries, and we are reminded that every technological triumph must be paired with thoughtful stewardship of the world it transforms.