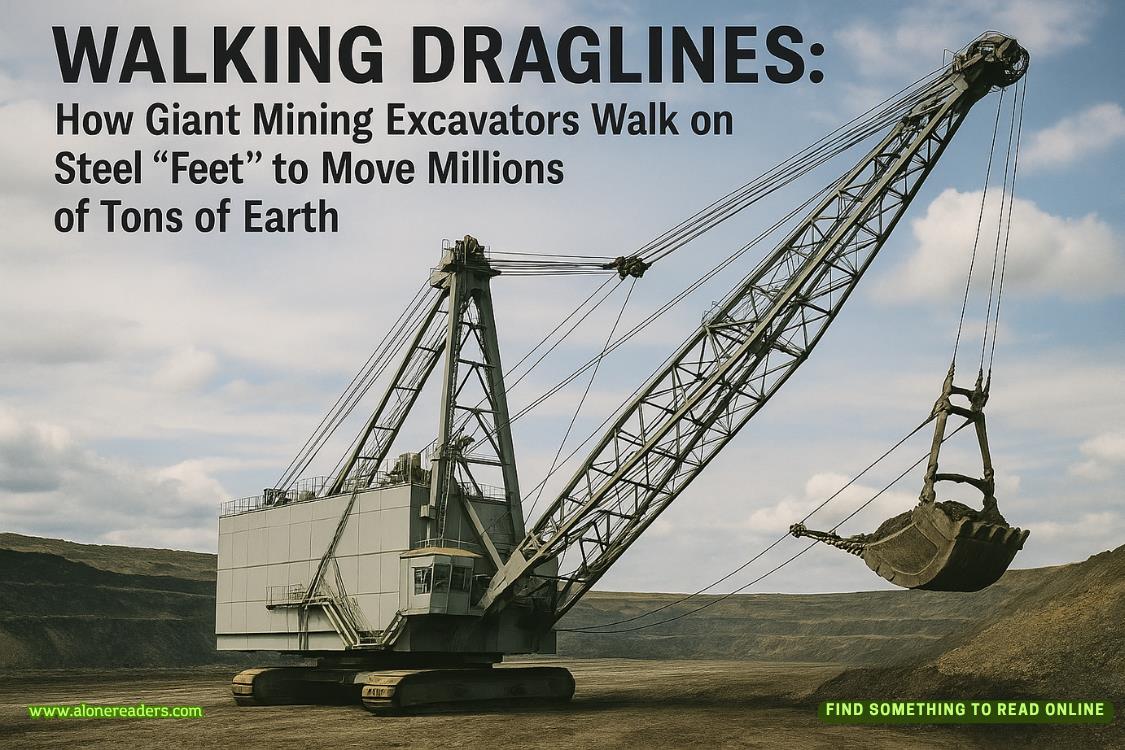

Walking draglines are among the largest mobile excavating machines ever built, towering over surface mining sites with booms stretching the length of football fields and buckets capable of lifting dozens of cubic meters of earth at a time. Their unusual nickname comes from their remarkable ability to “walk,” moving across terrain not on wheels or tracks, but on massive steel lifting mechanisms that resemble giant mechanical feet. They are the undisputed champions of bulk earthmoving, used primarily in open-pit coal mining and other large-scale mineral extraction operations where vast volumes of overburden must be removed efficiently. Their scale, cost, and engineering complexity place them in a class of their own, and understanding how they are designed, operated, and maintained reveals just how extraordinary these machines are.

The concept of the dragline excavator originated in the early 20th century, and as demand for energy and raw materials grew, so did the size of these machines. Initially mounted on tracks or stationary platforms, engineers soon discovered that transporting such massive machinery over rough mine terrain was impractical when using conventional mobility systems. This challenge led to the innovation of the walking mechanism, first introduced mid-century as mines expanded and required equipment that could relocate frequently to follow varying seams of deposit. Instead of rolling, the machine lifts its entire body with large cam-like shoes, shifts forward, and sets itself down in a rhythmic motion. Its movement is slow, sometimes only a few meters per hour, but mobility is never the primary purpose; stability and power are.

A walking dragline is built around a central revolving platform, called a revolving frame, on which the operator cab and boom assembly are mounted. The boom can measure anywhere between 60 and 120 meters, supported by an intricate network of steel cables and lattice structures that give it strength without excessive weight. At the end of the boom hangs a bucket connected by hoist and drag ropes. The bucket is cast forward into a pit, dragged back along the ground to collect material, then raised and swung to a desired dump location. This method of excavation is exceptionally efficient for horizontal scraping over long distances, which is why draglines are preferred for stripping overburden rather than digging vertically.

The body of the dragline, called the tub, acts as its foundation. It rests on enormous steel plates and feet that carry tremendous load forces. When it is time to move, hydraulic or mechanical jacks raise the tub slightly while curved walking shoes shift forward, pivoting on cams that resemble oversized rocker arms. The dragline’s weight can exceed thousands of tons, and every step requires a carefully controlled lifting sequence to prevent tipping, structural stress, and terrain damage. Engineers design the walking system to minimize ground pressure, allowing the machine to move across softer soils without sinking. Because of this unique mechanic, walking draglines can progress across mine sites where trucks or tracked machines might fail.

Dragging earth with a suspended bucket is a highly energy-efficient process. Unlike loaders or shovels that must overcome significant vertical resistance, a dragline uses the leverage of its long boom and cables to scrape across surfaces with surprising ease. This efficiency translates into reduced fuel consumption and lower operating costs. Modern draglines are relatively slow in bucket cycles compared to hydraulic shovels, but their bucket volume is so immense that they remove astonishing volumes of earth in fewer movements. This makes them ideal for continuous stripping operations, particularly in open-cut coal mines where seams can span hundreds of hectares.

Powering these leviathans is a dedicated electrical system, supplied directly from the mine’s grid via trailing cables. Electricity is favored due to the enormous energy demand, which would be impractical for diesel fuel alone. Electric motors drive hoist gear, drag systems, swing mechanisms, and the walking feet. Since the machine can operate for years in the same region of a mine, the electrical infrastructure is built to accommodate routine relocation of cables and substations. Control systems have evolved dramatically, with modern draglines featuring computer-assisted operation, automated cycle tracking, and real-time load monitoring to reduce component stress.

The engineering challenges involved in constructing a walking dragline are immense. Since these machines are too large to transport fully assembled, they are shipped in components to the mine site and constructed in a gradual assembly process lasting months. Specialized heavy lifting equipment and teams of skilled technicians are required to erect the lattice boom, align the colossal gears, and fine-tune the walking mechanism. The cost of a single unit can exceed hundreds of millions of dollars, and the decision to invest in one is based on long-term production projections, fuel cost calculations, and regional environmental regulations.

Maintenance is another crucial aspect of dragline operation. Because of their size, most repairs must be done on site, often while the dragline remains partially assembled. Engineers monitor wear on boom cables, inspect weld joints for fatigue, and continually lubricate key bearings and gears. Bucket teeth, subject to abrasive wear from rock and soil, must be replaced frequently. The walking cams, although built from hardened steel, require precise machining and periodic refurbishment to maintain walking stability. Environmental exposure introduces further complexities—dust infiltration, corrosion, and thermal expansion all influence structural integrity. Because downtime can cost thousands of dollars per hour in lost productivity, preventive maintenance schedules are strictly enforced.

The impact of walking draglines on mining efficiency has been transformative. Their ability to remove large volumes of waste rock with minimal ground disturbance reduces the footprint of auxiliary equipment such as trucks and loaders. Fewer haul roads must be constructed, and the reduced reliance on diesel-powered vehicles lowers the environmental emissions associated with mineral extraction. Their walking mechanism also eliminates the need to dismantle and relocate the machine via heavy transport vehicles when shifting work areas. By simply walking short distances daily, they can follow shifting mine boundaries and adapt to changing excavation plans.

Environmental considerations have shaped modern dragline design and operation strategies. Many jurisdictions require progressive rehabilitation of mine sites throughout the life of a project, and draglines play a role here as well. After overburden is removed, spoil piles can be shaped using dragline buckets to create slopes that mimic natural topography. This makes reseeding efforts and ecological recovery more successful. Additionally, because draglines operate electrically, they produce no onsite exhaust emissions, especially beneficial if the mine’s power supply incorporates renewable sources.

Operator skill is another dimension of dragline productivity. Operating a dragline requires deep spatial awareness and mastery of three simultaneous motions: swinging the boom, dragging the bucket, and hoisting material. Veteran operators often develop intuitive control patterns, minimizing wasted motion and optimizing bucket fill. Modern training systems employ simulators modeled after flight training technologies, allowing new operators to practice real-world scenarios without risk to machinery.

Despite their impressive capabilities, walking draglines are not suited for every mining environment. Very deep pits often favor truck-and-shovel systems due to the vertical nature of extraction. Additionally, the enormous capital cost restricts their use to mines with long operational horizons. When a mine transitions into reclamation or becomes economically unviable, draglines may be retired in place, disassembled, or occasionally sold and reassembled elsewhere. Because of their size, relocating an entire dragline is a rare and complex operation, sometimes requiring months of planning and preparation.

As mining technology continues to advance, the future of walking draglines blends classic mechanical engineering with digital automation. Improvements in structural materials such as high-strength steel can reduce boom weight and allow even larger buckets. Integration of artificial intelligence and machine learning can optimize digging cycles, predict wear patterns, and analyze terrain stability in advance. Electrical systems are integrating variable-frequency drives, improving power efficiency and reducing mechanical shock loads. Remote operation is emerging as a possibility, potentially removing operators from dangerous environments entirely.

Walking draglines stand as monuments to human engineering ambition, solving a uniquely difficult challenge: how to move thousands of tons of machinery across rugged terrain without wheels or tracks, all while excavating millions of cubic meters of earth. Their ability to walk, their efficiency in stripping operations, and their central role in surface mining have kept them relevant for decades. They represent the intersection of power, precision, and innovation, and although massive and slow, these gentle giants are indispensable to large-scale resource extraction. In a world increasingly conscious of environmental impacts, future dragline designs may evolve toward greater energy efficiency and intelligent control, but the fundamental engineering principles behind these “walking” colossi will continue to inspire awe in anyone who witnesses them in motion.